Authors:

Subbiah Seenivasan1* and Narayanan Nair Muraleedharan2

1The Institute of Environmental and Human Health, Texas Tech, University, Lubbock – 79415, Texas, USA

2Tea Research Tea Research Association, Tocklai Experimental Station, Jorhat-78500, Assam, India

Received: 04 September, 2015; Accepted: 15 September, 2015; Published: 18 September, 2015

S. Seenivasan, The Institute of Environmental and Human Health, Texas Tech University, Lubbock – 79415, Texas, USA, Tel: +001-806-885-4567; Fax : +001-806-885-2132; E-mail:

Seenivasan S, Muraleedharan NN (2015) Dissipation Behavior of Fenpyroximate Residues in Black Tea and Brew. Int J Agricultural Sci Food Technology 1(1): 003-006. DOI: 10.17352/2455-815X.000002

© 2015 Seenivasan S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Fenpyroximate; Acaricide; Dissipation; Tea

Fenpyroximate is an effective acaricide on several food crops. In the present study, dissipation of residue of this acaricide in black tea, tea infusion and spent tea was studied. Analysis was carried out using high performance liquid chromatography with diode array detection. The rate of dissipation was found to vary with the nature of the substrate. In tea leaves the half-life of fenpyroximate ranged from 2.20 to 4.22 days. The residue of fenpyroximate was not detectable in the tea brew.

Introduction

The red spider mite Oligonychus coffeae the most important mite pest of tea. This mite infests tea leaves, leading to their discoloration and defoliation, ultimately leading to crop loss ranging from 15-17 % [11. Muraleedharan N, Chen ZM (1997) Pests and diseases of tea and their management. J Plantn Crops 25: 15-43.,22. Chen ZM, Haibin W (1998) Factors affecting residues of pesticides in Tea. Pestic Sci 23: 109-118.]. The mite though is preyed upon by a few predators, use of acaricides become inevitable in case of severe infestation. The chemicals commonly used to control this pest are dicofol, fenpropathrin and propargite in addition to a formulation containing an eotomopathogenic fungus, Paecilomyces fumosoroeseus. Recently a new molecule fenpyroximate was evaluated for its effects against the red spider mite of tea. Application of this acaricide was found to give satisfactory control of the red spider mite. The present study was carried out to evaluate the residues of fenpyroximate in black tea, tea infusion and spent tea resulting from the foliar application of the miticide. As black tea is subjected to infusion prior to consumption, residues of pesticides in tea and its transfer in to the brew need to be monitored. A few papers have been published to describe the losses of residues from black tea and during infusion in hot water [33. Rajukkannu K, Blasubramanian M, Vasudevan P (1981) Residues of dicofol and tetradifon in tea leaves. J Plantn Crops 9: 124–125.-66. Jaggi S, Sood C, Kumar V, Ravindranath SD, Shanker A (2001) Leaching of pesticides in tea brew. J Agric Food Chem 49: 5479-5483.].

Materials and Methods

Field trials

Two field experiments were conducted in Valparai (Latitude 10° 20' N; Longitude 77° 00' E; Hilly terrain, Coimbatore Dist.) and Gudalur, (Latitude 11° 29' N; Longitude 76° 30' E; Hilly terrain, Nilgiris Dist.) (Tamil Nadu, India) situated at an elevation of 1000 - 1150 m above MSL. Plots measuring 100 sq.m containing tea plants of mixed jats with appropriate guard rows were used for the study. These tea plants had been planted in double hedge planting system at a spacing of 0.75 x 0.75 x 1.35 m under the shade tree, Grevillea robusta (6 x 6 m spacing). The bushes in the experimental plots in Valparai were last pruned during April 2002 while those at Gudalur were pruned at a height of 60 cm above ground level. The treatments included foliar spraying of fenpyroximate 5 EC (Emulsifiable Concentrate ) @ 500 and 1000 mL ha-1 (25 and 50g a.i. ha-1) and an untreated control. Each treatment was replicated in seven plots. Tea shoots consisting of three leaves and a bud were harvested on '0' (3 hours after spraying), 1st, 3rd, 5th, 7th, 10th and 14th day after application of fenpyroximate. Spraying was carried out with hand operated knapsack sprayer using a spray volume of 400 L ha-1. The shoots harvested at each harvest were processed in miniature manufacturing unit. Harvested tea shoots were spread in a withering trough and allowed to wither with natural air blown underneath the trough for 16-18 hours. Withered leaves were passed through a rotorvane for crushing and mixing of leaves and juice. This was passed four times through a roller cut CTC (Crush, Tear and Curl) machine. The resultant “Cut dhool” was spread over the fermentation trays at a thickness of about 2 cm, maintaining a relative humidity of about 90-95% for one hour. Fermented dhool was dried in a mini fluid bed drier to attain a final moisture content of 2.5 – 3.0% [77. Ramasamy V (1993) CTC Tea Manufacture, United Planters' Association of Southern India, Coonoor India.]. Black tea samples thus obtained were analyzed in High Performance Liquid Chromatography (HPLC) equipped with diode array detection (DAD), following standardized procedure.

Analytical standards and working solutions

An analytical standard of fenpyroximate and other commercial grade Pyroxcel (5% a.i.) were supplied by Excel Crop Care Ltd., Mumbai. Standard solutions (1000 mg L-1) were prepared in acetonitrile and the solutions required for preparing a standard curve (0, 0.03, 0.1, 0.2, 0.4, 0.5, 1.0, 2.0, 5.0 and 10.0 µg mL-1) were prepared from the stock solution by serial dilutions. All the solvents used were of Analytical grade from S.D. Fine Chemicals.

Apparatus

A high performance liquid chromatograph, Agilent model 1100, equipped with diode array detection, Zorbax RX-C18 endcapped (25cm long x 0.45 µm) column was used. The mobile phase was Acetonitrile: Water (75:25 v/v) at the flow rate of 1.0 mL min-1. Detection was done at a wavelength of 235nm selecting the best chromatogram option (injection volume 10µL).

Alumina column

Glass column (30 x 1.1 cm, i.d.) with teflon stop-cocks were packed from the bottom with cotton plug and 25g neutral alumina between the layers of anhydrous sodium sulphate.

Method validation

a. The analytical method was validated for black tea and prior to the actual analysis. The methodology for analysis of residues of fenpyroximate in tea was validated for parameters such as specificity, selectivity, linearity, system precision, repeatability and reproducibility by following guidance document on residue analytical methods [88. (2004) SANCO/825/00, rev 7.-1010. EURACHEM Guide (1998) The Fitness for Purpose of Analytical Methods A Laboratory Guide to Method Validation and Related Topics. Guidance document on residue analytical methods, ISO 3103: (1990). ]. For determination of recovery per cent of fenpyroximate from black tea samples, 10g untreated control samples were fortified at 0.1, 1.0, 10.0 mg kg-1 level, by adding a standard fenpyroximate solution, and replicated three times, separately. After mixing and allowing the solvent to evaporate, the samples were analyzed for the concentration of fenpyroximate residues as described below. Quantification was accomplished by using a calibration curve prepared by serial dilutions (concentration 0 – 10 µg mL-1) of the stock solution, which was prepared in acetonitrile and stored in an amber colored bottle. The minimum concentration with signal to noise ratio (S/N) of 3:1 was considered as the limit of detection (LOD) and the signal to noise ratio (S/N) of 10:1 was fixed as the limit of quantification (LOQ). Good linearity was achieved in the range of 0 – 10 µg mL-1. The system precision was determined with a intermediate standard solution of concentration 5 µg mL-1. To ensure the specificity and selectivity of the method towards the analyte, the following sequence of injections was carried out:Solvent used for the preparation of reference standard

b. Reference standard (in order to determine the retention time

c. Test substance (Fenpyroximate formulation)

d. Blank extract from the matrix (Un-treated control black tea)

e. Spiked sample at the concentration at 1.0 µg mL-1

Black tea analysis

Ten grams of processed black tea was hydrated with 2 mL of double distilled water and extracted with 100 mL of methanol by shaking in a mechanical shaker for two hours. The contents were filtered, through Celite 545, washed with 100 mL of methanol and the extract was concentrated in a rotary vacuum evaporator with the water bath maintained at 40 °C. The concentrated residue was dissolved in methanol and transferred to a 500 mL separating funnel. To the methanol extract, 50 mL of saturated sodium chloride solution and 50 mL of hexane were added and shaken vigorously. After allowing the layer to separate, hexane layer was allowed to pass through the anhydrous sodium sulphate placed in the funnel. The aqueous extract was repeatedly extracted four times with fresh hexane (50 mL each time) and the hexane layer was collected into the 500 mL round bottom flask. The hexane extract was concentrated in a rotary vacuum evaporator with the water bath maintained at 40 °C. The concentrated residue was dissolved in hexane and transferred to glass column packed with neutral alumina (25 g). A layer of anhydrous sodium sulphate, at 1 cm thickness was packed at the top and bottom of alumina. Prior to elution, the column was washed with 50 mL of hexane to remove the co-extractives and the washings were discarded. The compound was eluted with 100 mL of 30% ethyl acetate in hexane. After evaporation, the samples were suitably diluted with acetonitrile and analysed in High performance liquid chromatograph equipped with diode array detector.

Tea infusion

The black tea samples manufactured in the miniature CTC unit were subjected to infusion process. Infusions were prepared using tap water in a stainless steel kettle. Two grams of black tea samples were immersed in 100 mL of boiling water and allowed to brew at boiling temperature for about 6 minutes [1111. IS 6400: (1993). Indian Standard. Method for preparation of tea infusion for sensory evaluation (I rev.). Bureau of Indian Standards, Manak Bhavan, New Delhi.-1313. Nagayama T (1996) Behaviour of residual organophosphorus pesticides in foodstuffs during leaching or cooking. J Agric Food Chem 44: 2388-2393.]. After brewing, the tea infusion was filtered through stainless steel tea strainer cartridge and cooled. The spent tea leaves left after brewing were collected and air dried. Both the infusion and the spent leaves left after brewing process were separately analyzed for residues. The tea brew was transferred to a separating funnel and subjected for partitioning with hexane (3 times x 100 mL). The hexane layer was allowed to pass through anhydrous sodium sulphate. The combined hexane layer was collected in 250 mL round bottom flask and concentrated to dryness using rotary vacuum evaporator at 45º C. The residue was reconstituted in appropriate solvent and quantified in HPLC.

Results and Discussion

Method validation

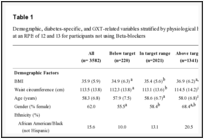

The residue analysis in tea matrices and detection of fenpyroximate were performed according to the method for recovery maximisation by the authors. Recoveries were measured by comparing peak areas of the spiked samples with external standards in acetonitrile and matrices matched control prepared from unfortified tea extracts. The specificity of this method indicated that there was no interference from the solvent and matrix. Quantification was accomplished by using standard curve prepared by stock solution in acetonitrile. A good linearity was achieved between the range of 0.1- 1.0 µg mL-1 and 1.0 – 10.0 µg mL-1 with a correlation coefficient of 0.9991. The column was conditioned by repeated injections (3) of standards and sample extracts until HPLC peaks were reproducible. Recoveries of the pesticide at different fortification levels i.e. 0.1, 1, and 5 mg Kg-1 were determined in six replicates from black tea matrix to evaluate the accuracy of the method. The precision of the method was determined by analyzing the tea samples at the 1.0 mgKg-1 spiked level with six replicates by different analyst and different day. The mean recoveries of the pesticide at difference fortification levels validated the procedures adopted for extraction and analysis of fenpyroximate residues from tea samples. The recovery achieved was 85.90% at 0.1 mg/kg level of fortification, 93.25% at 1.0 mg kg-1 level and 98.36% at 10.0 mg kg-1 level of fortification for tea which was a clear validation of the procedure adopted for the extraction and analysis of fenpyroximate from tea samples. The recoveries obtained for all the substrate were in the acceptable range of 85.90-98.36% with the mean relative standard deviation of 14.30%. The detection limit of the instrument was 0.03 µg mL-1 (using serial dilution of technical standards) and the limit of quantification from the tea matrix was 0.1 mg Kg-1 . But earlier studies indicated that the mean recovery of fenpyroximate in fruits, vegetables and tea was 78-85%. The half-life value and rate constant were calculated [1414. JMPR (1995) Evaluation of fenpyroximate. Unpublised.]. The residue level of fenpyroximate in made tea at tested dosages both wet and dry seasons at different harvest intervals are given in Table 1.

Fenpyroximate in black tea

In black tea, the degradation pattern and half-life of fenpyroximate varied according to location. The dissipation rate of fenpyroximate in tea exhibited first order kinetics. The regression equations, half-life values and rate constant for fenpyroximate in wet and dry seasons are summarized in Table 2.

The residue level of fenpyroximate in black tea samples obtained from the experiment conducted at Gudalur in dry season was lower in comparison to the residues in the samples from Valparai. In Valparai, the mean sunshine period during the experiment (0 – 7 day) was 5 h day-1 while the maximum temperature ranged between 24ºC and 26ºC during 0 to 10 days after application. In Gudalur, the mean sunshine period during the experiment (0 – 7 day) was 7 h day-1 and the maximum temperature ranged between 28ºC and 32ºC during 0 to 3 day after application. The prolonged sunshine hours and higher temperature in dry weather period at Gudalur probably favoured faster degradation of fenpyroximate. A study on photolysis conducted elsewhere indicated that more than 80% of initial residue in the aqueous solution of fenpyroximate decomposed when it was exposed to sunlight [1515. Nagayama T, Maki T, Kan K, Iida M, Tamura Y, et al. (1996) Residues of organophosphorus pesticides in commercial tea and their leaching into tea. Nippon Noyaku Gakk 14: 39-45.]. This appears to be the reason for the lower level residues on '0' day at Gudalur, where the chemical was exposed to sunlight for a longer period. This study proved that residue of fenpyroximate when sprayed at the recommended dosage of 10th day black tea samples was lower than 1.01 mg Kg-1, which is well the maximum residue limit of 10 mg Kg-1 of tea in Japan.

-

Table 2:

Half-life and other statistical parameters for fenpyroximate dissipation in tea.

Leaching of residues from manufactured tea to infusion

The residue leached in to the infusion was below the level of detection. In other words, there was no transfer of fenpyroximate residues from black tea in to the brew. Nearly 95% of the residues remained in the spent leaves. Generally, only those pesticides with high water solubility are potentially transferred to the tea brew in significant amounts. The rate of leaching of the pesticide residue in to the infusion depends on its solubility in water (The Pesticide Manual, 2003) and partition coefficient [66. Jaggi S, Sood C, Kumar V, Ravindranath SD, Shanker A (2001) Leaching of pesticides in tea brew. J Agric Food Chem 49: 5479-5483.,1616. Chen ZM, Wan HB, Xia HL (1994) Prediction on degradative rates of pesticides on tea plant made tea and infusion. Biochem Biophy Res Commun 189: 689-693. ]. Solubility of this acaricide in water solubility is 1.46 x 10-2 mg L-1 at 20ºC and log Kow 5.01.

Conclusions

The dissipation of fenpyroximate on tea leaves was affected by weather conditions. The acaricide persisted in made tea a little longer during dry season compared to wet season. On the basis of the above findings it can be concluded that there was no leaching of residues from black tea in to the infusion in both the seasons. Thus, the consumption of infusion is safe, when tea shoots are harvested after the safe harvest interval and processed with black tea.

Acknowledgements

The authors are grateful to the Tea Board, Govt. of India for the financial assistance under X five year plan.

- Muraleedharan N, Chen ZM (1997) Pests and diseases of tea and their management. J Plantn Crops 25: 15-43.

- Chen ZM, Haibin W (1998) Factors affecting residues of pesticides in Tea. Pestic Sci 23: 109-118.

- Rajukkannu K, Blasubramanian M, Vasudevan P (1981) Residues of dicofol and tetradifon in tea leaves. J Plantn Crops 9: 124–125 .

- Singh RP, Agnihotri NP (1984) Residues of dicofol, endosulfan and Malathion on tea, Camellia sinensis (L.) O. Kuntz. J Ent Res 8: 14-16 .

- Manikandan KN, Muraleedharan N, Selvasundaram R (2001) Residues and persistence of chlorpyrifos in processed black tea. J Plantn Crops 29: 35-37.

- Jaggi S, Sood C, Kumar V, Ravindranath SD, Shanker A (2001) Leaching of pesticides in tea brew. J Agric Food Chem 49: 5479-5483 .

- Ramasamy V (1993) CTC Tea Manufacture, United Planters' Association of Southern India, Coonoor India.

- (2004) SANCO/825/00, rev 7.

- AOAC (2002) AOAC Guidelines for Single Laboratory Validation of Chemical Methods for Dietary Supplements and Botanicals.

- EURACHEM Guide (1998) The Fitness for Purpose of Analytical Methods A Laboratory Guide to Method Validation and Related Topics. Guidance document on residue analytical methods, ISO 3103: (1990).

- IS 6400: (1993). Indian Standard. Method for preparation of tea infusion for sensory evaluation (I rev.). Bureau of Indian Standards, Manak Bhavan, New Delhi.

- Muraleedharan N (2004) Strategies for reducing pesticide residues in tea. Inter. J Tea Sci 3: 105-109.

- Nagayama T (1996) Behaviour of residual organophosphorus pesticides in foodstuffs during leaching or cooking. J Agric Food Chem 44: 2388-2393 .

- JMPR (1995) Evaluation of fenpyroximate. Unpublised.

- Nagayama T, Maki T, Kan K, Iida M, Tamura Y, et al. (1996) Residues of organophosphorus pesticides in commercial tea and their leaching into tea. Nippon Noyaku Gakk 14: 39-45 .

- Chen ZM, Wan HB, Xia HL (1994) Prediction on degradative rates of pesticides on tea plant made tea and infusion. Biochem Biophy Res Commun 189: 689-693.

Table 1:

Fenpyroximate residue in black tea and its brew.